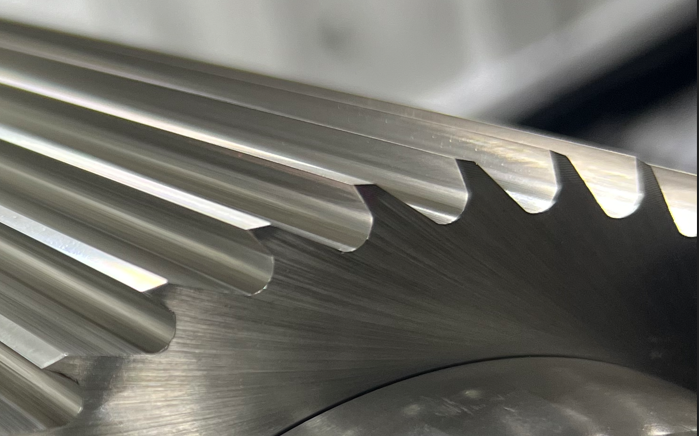

The re-grinding of cutting rotors and cross-cutting knives requires a great deal of know-how, employee experience and latest grinding machine.

Preservation of the original tooth geometry is decisive for cutting quality, service life and product quality. Up to a diameter of 350mm and a length of 1,700mm for rotors, as well as a maximum length of 5,900mm in cross-cutting knives, we cover the market’s entire grinding spectrum. An exact concentricity of the cutting rotors, and an exact flatness of the cross-cutting knife and recycling knife are crucial for the adjustment of the cutting gap.

The Certificate of Quality issued following each grinding service performance underlines our high standards of reliability and competence.

Your benefits

/ Minimal reduction in diameter ensures many re-sharpening cycles

/ Preservation of the original tooth profile guarantees a proper cut

/ Higher quality standards due to well-trained personnel and quality inspection

/ Optimal value